Here is a little Q&A that Works Connection has put together, just in case you have more questions. If you are looking to purchase any Works Connection products you can use the code Keefer20 to save 20% off any WC product. Oh and if you’re on a WP Cone Valve fork WC offers a special ring for those forks, FYI!

Q. What’s included with each Pro Launch?

A. Every Pro Launch includes a fork ring, trigger assembly, drill guide, countersink and

Any supplementary hardware required for specific models is included at no additional cost.

Q. Why isn’t the Pro Launch made to be universal with one kit fitting all bikes?

A. We feel there are too many variables to produce a reliable ‘One size’ fits all Pro

Launch.

Does a ‘one size’ pair of shoes sound like a good fit for everyone?

Our design team tailors each fork ring, trigger assembly and instruction templates for the specific year/make/model to ensure an exact fit that yields consistent, dependable, long term performance.

Q. Why doesn’t the Pro Launch use a split/hinged fork ring?

A. While you might save a few minutes of installation time with a hinged fork ring,

our design provides a lighter, yet stronger and more reliable fork ring that eliminates the potential failure of a split/hinged ring.

Q. Who designed and who manufactures the Pro Launch?

A. Our in-house design team is responsible for the patented design and manufacturing,

along with packaging, is done right here in Nor-Cal, USA!

Q. What purpose do the fork guard straps serve and do they cost extra?

A. Some brands (e.g. Honda) use a softer fork guard material and the fork

straps provide the necessary reinforcement. And for those applications the fork

guard straps are included at no additional charge.

Q. Can you set the Pro Launch by yourself?

A. Yes. While sitting on the bike, lean over the bars and pull up on the trigger with your

right hand. Then grasp the front wheel with your left hand and pull the forks down far

enough so the trigger and fork ring mate.

Q. How does the trigger operate?

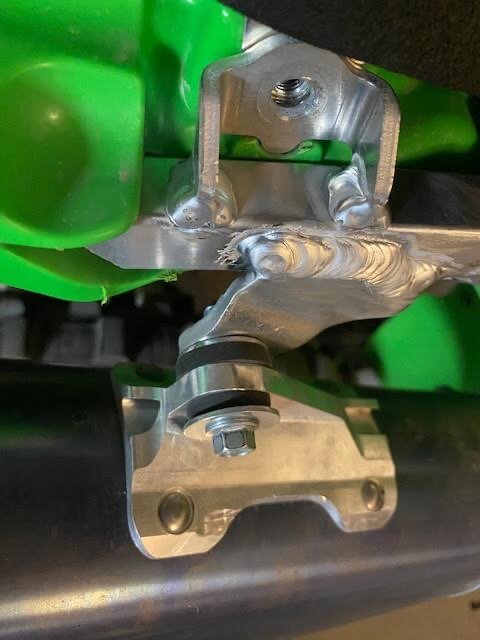

A. You simply lift the trigger while depressing the forks and the trigger and fork ring

self-latch and mate smoothly. Once you get to the first turn and apply the front brake

the trigger releases from the fork ring and retracts via strong magnets to its resting

position. The resting position of the trigger makes it impervious to a rock strike

accidentally engaging the mechanism.

Q. Does the Pro Launch add weight to a bike?

A. The Pro Launch weighs in at 50 grams (1.76 ounces) making it the lightest on the

market.

Q. How long does it take to install the Pro Launch?

A. Typical installation time is about 30-40 minutes.

Q. How do I know where to mount the trigger and fork ring?

A. Our step-by-step instructions include a bike specific paper template for the trigger

location and photographs to illustrate the fork ring location. These instructions are

included with every Pro Launch and are available to download from our website.

Q. Can you service the Pro Launch.

A. We assemble the Pro Launch onsite so we have every replacement item available.

Q. Who uses Pro Launch?

A. Anyone looking for the advantage in getting off the start gate first. That includes

amateur riders on minis all the way up to Factory Pro Teams.

Q. Where can I get a replacement paper template?

A. On our website navigate to your Make/Model/Year, select the Pro Launch page and

it’s available to download by clicking on ‘Instructions’.

Q. What if my bike isn’t listed?

A. E-mail info@worksconnection and we’ll get you an answer.

Q. Will the Pro Launch work with aftermarket fork guards.

A. The Pro Launch is designed for use on the stock, OEM fork guards.